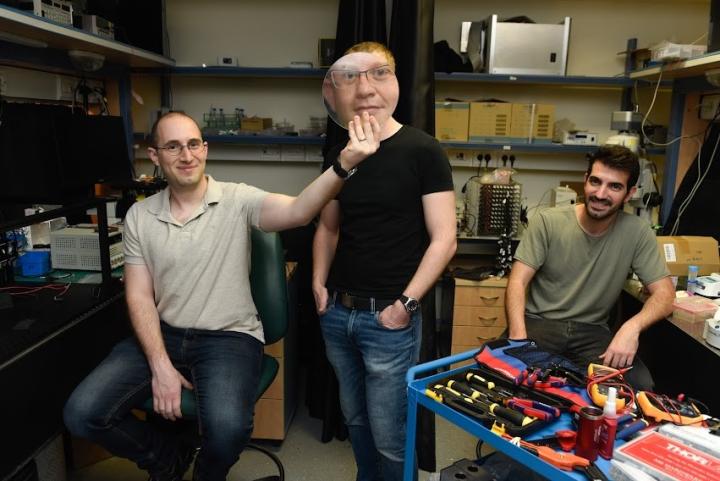

The joint FLUTE (Fluidic Telescope) project, between NASA and Prof. Moran Bercovici’s research group at the Technion's Faculty of Mechanical Engineering, has reached the second round of NASA's prestigious NIAC competition for breakthrough technologies. FLUTE will now receive $600,000 in funding over two years to study the feasibility of launching a giant space telescope – whose mirror will form, by itself, in space, thanks to the fundamental physical property of surface tension of liquids. On the NASA side, the project is being led by Prof. Edward Balaban of the Ames Research Center.

"NIAC (NASA Innovative Advance Concepts) is NASA's flagship project to support innovative projects, the really crazy ideas," laughs Prof. Bercovici in an interview for the Israel Space Agency website. "Two weeks ago, we received the heart-warming announcement that we had moved on to the second round. This is a very serious screening – hundreds of proposals were submitted for the first round – and now six projects have progressed to the second round. In the third round, additional screening will be conducted, and those who remain will receive additional, even larger funding, in the hope that in the end we will be able to launch a demonstrator into space."

The bottleneck of space observatories

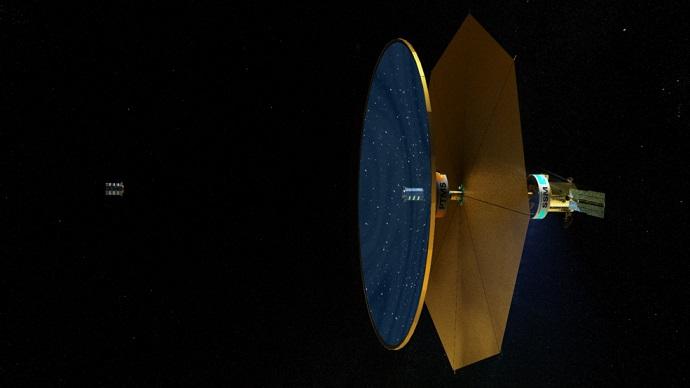

FLUTE is designed to launch, into space, telescopes with a diameter of 50 meters or more, which, among other things, will allow humanity to observe directly exoplanets – and to search for life on them. The bottleneck of space telescopes is the mirror: the construction of the James Webb Space Telescope took about 25 years and cost about $10 billion. The main reason for the high cost and complexity of the mission is that the diameter of James Webb's mirror is six and a half meters, while the inner diameter of the rocket that launched it into space is only four meters. Therefore, the mission engineers had to divide the mirror into 18 mirrors, fold them before the launch and re-arrange them in space in a delicate and complex “choreography”.

Ahead of Eytan Stibbe's launch into space, Prof. Bercovici explained, "If we want to photograph exoplanets, we will need a space telescope with a mirror that is tens and hundreds of meters – and that is impossible. We don't have the technology to launch skyrockets hundreds of meters in diameter. Therefore, it makes sense to produce the optics in space. And while there's already a three-dimensional printer on the International Space Station, that can print almost anything, a mirror like James Webb's needs to be smooth at nanoscale resolution, and 3D printers don't reach that level of resolution. Furthermore, you can't polish the mirror in space either, because it's a messy process that requires a lot of energy and heavy industrial equipment."

The Technion scientists’ solution is simple: use the basic physical property of the surface tension of liquids. "Thanks to the surface tension, liquid surfaces are naturally very smooth. If we pour water into a glass, the water molecules will align themselves until the water surface is completely smooth – with differences of less than a nanometer. It's a free gift from nature. Under microgravity conditions in space, the water we pour will also take on a spherical shape – which is a good starting shape for optics. So, we are taking advantage of the well-known property of the surface smoothness of the liquid, and using microgravity to get a smooth, spherical droplet – similar to a drop of dew on a leaf."

From hand-injection lenses to telescope mirrors

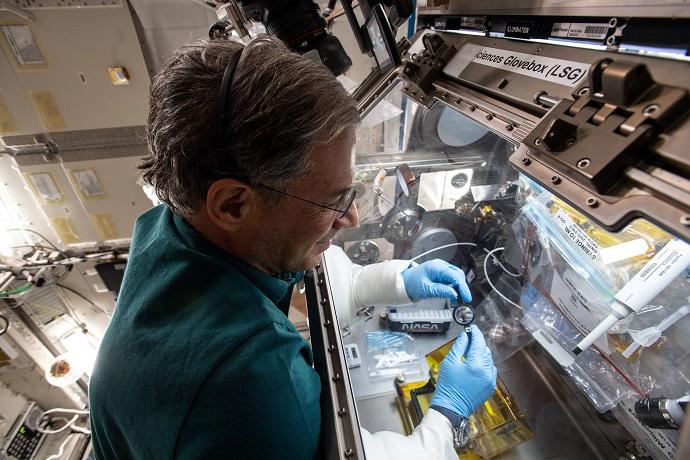

In 2022, as part of a space mission, funded by the Israel Space Agency, the second Israeli astronaut, Eytan Stibbe, demonstrated the basic idea behind FLUTE by injecting polymers –materials, in a liquid state, that can be solidified, such as plastic – into a series of rings between 3 and 15 cm in size. Under micro-gravity conditions, a lens is created on both sides of the ring. In the second stage, Stibbe used ultraviolet light to solidify the polymers, and so he created a series of concave and convex lenses. After landing back on Earth, Bercovici and his colleagues tested the optical properties of the lenses created in this way.

It should be noted that lenses are necessary for staying in space: in the astronauts’ helmets, optical sensors in the spacecraft, in medical devices and, of course, in cameras. Long-range manned missions, such as to Mars, would have to be independent and manage without a supply of new optical components from Earth.

"Eytan's experiment was an actual demonstration, on the space station, that the technology does work," says Prof. Bercovici. "Since then, we have conducted more experiments in parabolic flight [a flight that simulates micro-gravity. O.C.], in which we have proven that we can also produce mirrors from liquids – since most telescopes in space use mirrors, not lenses. Now, after the NIAC’s encouraging announcement, we are advancing in two channels in parallel: we are continuing to refine and to enhance the precision of the technology, for example, in additional parabolic flights scheduled for us, together with NASA, in August, and also in planning the mission of the future telescope. We will have to plan, for example, how to fold the frame for the flight, how much fuel we will need, and to which point in space we should send the telescope. And in the third stage, we will build a small-scale demonstrator and launch it into space."